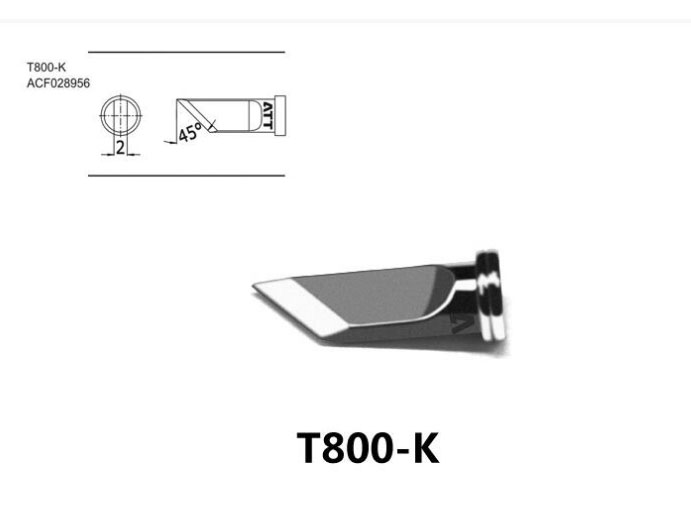

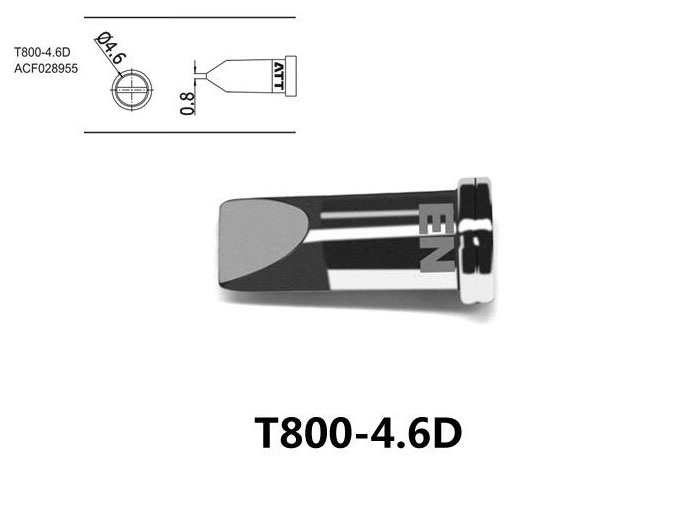

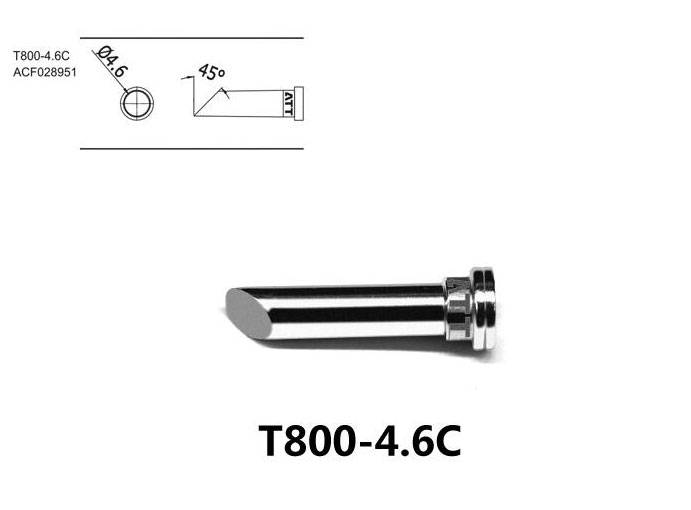

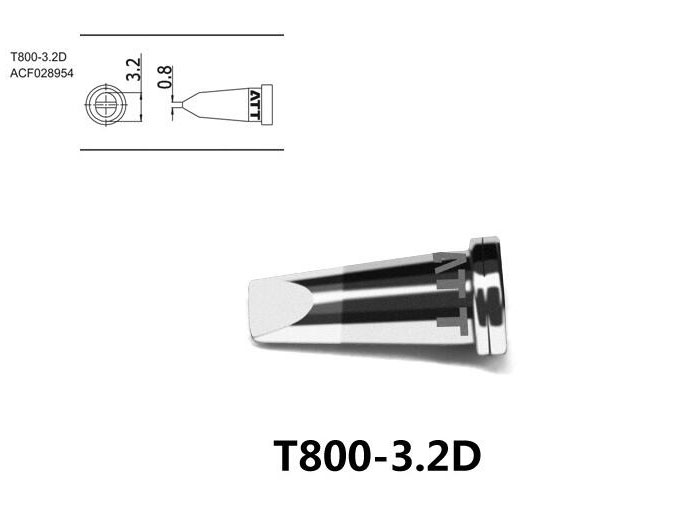

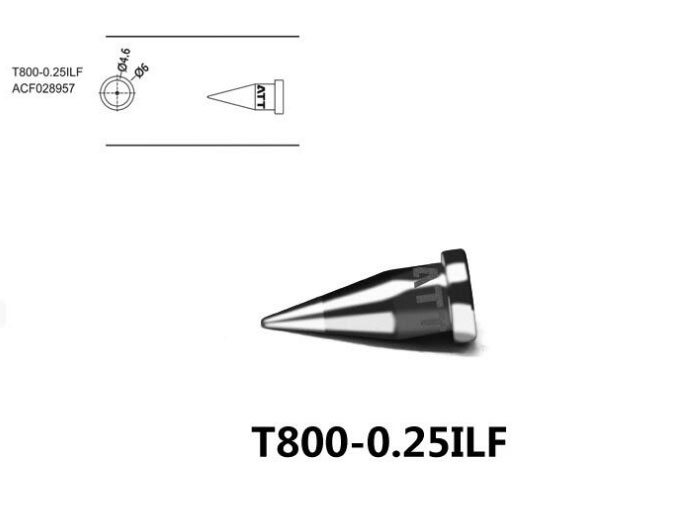

| Product Name | ATTEN tip T800-SK/T800-0.25I / T800-1.2C /T800-K /T800-0.25ILF/ T800-2.4D / for ST series soldering iron K head cutter head soldering iron tip |

| Item NO. | 857716 |

| Solder iron station | Solder tips |

| Weight | 0.05 kg = 0.1102 lb = 1.7637 oz |

| Category | Phone repair tools > Rework stations & tools |

| Tag | T800-0.25I , T800-1.2C , T800-K , T800-0.25ILF , T800-2.4D , T800-SK , T800SK , T800 1.2C , T800 0.25ILF , T800 2.4D , T800 SK , T800 , solder iron tip , solder tips |

| Brand | ATTEN |

| Creation Time | 2019-11-14 |

A. Size of the solder joint: Choosing the right camel head according to the size of the solder joint can make the work smoother.

The tip is too small and the temperature is not enough; too much, there will be a lot of solder melting, and the series control is difficult.

B. Solder Joint Intensiveness: Soldering on denser boards, using a finer tip can reduce the chance of tin bridge formation.A. Types of soldering components: Different types of electronic components, such as resistors, capacitors, SOJ chips, and SOP chips,

require the cooperation of different soldering iron tips to improve work efficiency.

B. Easiness of solder joint contact. If the solder joint location is surrounded by some higher electronic

components and is difficult to contact, a longer and younger tip can be used.

C. Tin content: If more tin is needed, a soldering iron tip with a larger tinned surface area can be used.

No related record found